The Importance of Rapid Prototyping Service for Business Success

In today's fast-paced and competitive market, businesses are constantly seeking ways to innovate and improve their products efficiently. One essential tool that has gained immense popularity among manufacturers, especially in the field of metal fabrication, is the rapid prototyping service. This process allows for quick turnaround times in product development, enabling companies to stay ahead of the curve.

Understanding Rapid Prototyping

Rapid prototyping refers to the process of quickly fabricating a scale model or a functional prototype of a physical part or assembly using 3D computer-aided design (CAD) data. The main goal of rapid prototyping is to accelerate the design and manufacturing processes, allowing companies to iterate their products swiftly and efficiently.

Why is Rapid Prototyping Service Essential?

The relevance of rapid prototyping service in the business landscape cannot be overstated. Here are the key reasons why it is vital for modern enterprises:

- Speed to Market: Companies can significantly reduce the time it takes to bring new products to market. By quickly creating prototypes, businesses can test their concepts rapidly and make necessary adjustments before the final production.

- Cost-Effectiveness: Although there is an upfront investment in prototyping, the overall cost of product development decreases. Early problem detection during the prototyping stage can prevent expensive changes later in production.

- Enhanced Innovation: The ability to visualize and test ideas in a tangible form encourages creativity and experimentation, fostering an innovative environment that can lead to breakthroughs.

- Improved Accuracy: Prototypes allow for testing and validation of designs before full-scale production, ensuring that the final product meets the desired specifications and performance requirements.

- Customer Feedback: Companies can obtain early feedback from potential customers by providing them with prototypes. This input is invaluable in fine-tuning the product to better meet market needs.

The Process of Rapid Prototyping

The process typically involves several key steps, including:

1. Design and CAD Modeling

The journey begins with creating a detailed design using CAD software. This model serves as a blueprint for the prototype.

2. Selecting the Right Prototyping Technology

There are various methods for rapid prototyping, including:

- Stereolithography (SLA): Utilizes a laser to cure resin layer by layer, creating highly accurate prototypes.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered materials, ideal for creating strong functional prototypes.

- Fused Deposition Modeling (FDM): A widely used method for 3D printing that lays down plastic filament layer by layer.

3. Prototype Fabrication

Once the design is finalized, the chosen technology is employed to create the prototype. This step is where rapid prototyping shines, as it offers the ability to produce the model quickly and efficiently.

4. Testing and Evaluation

After fabrication, the prototype undergoes rigorous testing. This step allows businesses to identify any deficiencies in the product design early on.

5. Revisions and Finalization

Feedback from testing leads to necessary revisions. The prototype may need several iterations before arriving at the final design, ensuring that the product is not only viable but optimized for the market.

Benefits of Using Rapid Prototyping Service in Metal Fabrication

For businesses within the metal fabrication industry, utilizing a rapid prototyping service brings specific advantages:

- Material Versatility: Advanced prototyping technologies can handle a variety of materials, including metals, plastics, and composites, offering flexibility in design.

- Precision Engineering: Metal prototypes created through rapid prototyping exhibit high precision and can be tested for performance under different conditions.

- Complex Designs: The technology allows for intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods.

- Reduced Waste: By validating designs early, companies can minimize waste associated with large runs of defective parts.

Applications of Rapid Prototyping in Various Industries

Rapid prototyping is not limited to a single sector; its versatility makes it beneficial across various industries. Some notable applications include:

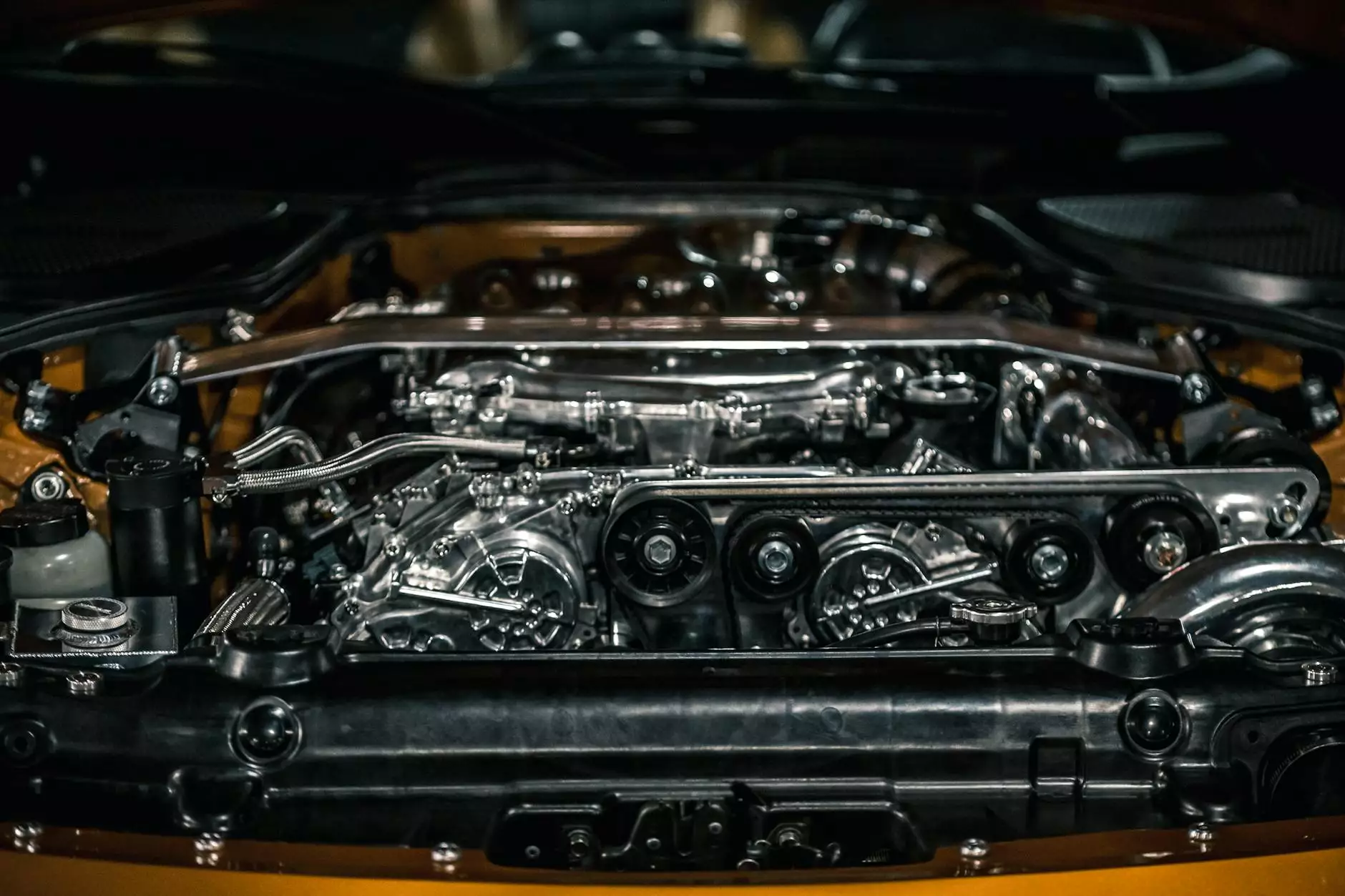

1. Automotive Industry

In the automotive sector, rapid prototyping is used to create components for testing, ensuring performance and safety before mass production.

2. Aerospace Industry

The aerospace industry relies on rapid prototyping to develop complex parts and systems, facilitating innovation while meeting stringent regulatory requirements.

3. Medical Device Manufacturing

In medical technology, prototypes allow for the design and testing of devices that must comply with strict standards of safety and efficacy.

4. Consumer Products

For consumer goods, testing prototypes can provide invaluable insights into user experience and functionality before launch.

Choosing the Right Rapid Prototyping Service Provider

When selecting a rapid prototyping service, consider the following factors:

- Experience and Expertise: Look for a provider with proven experience in your industry, particularly in metal fabrication.

- Technological Capabilities: Ensure that the service provider uses the latest technology to meet your prototyping needs.

- Quality Assurance: A top-notch prototyping service will have rigorous quality control measures in place to ensure the accuracy and reliability of prototypes.

- Cost Transparency: Choose a provider that offers clear pricing structures and discusses any potential additional costs upfront.

- Support Services: A reliable provider will offer comprehensive support, from initial concept discussions through to production and beyond.

Conclusion: Elevate Your Business with Rapid Prototyping

In conclusion, a rapid prototyping service is not just a luxury but a necessity for businesses aiming to thrive in a competitive market. By leveraging rapid prototyping, companies can accelerate their innovation processes, reduce costs, and improve product quality. It enables businesses to bring their ideas to life, ensuring that they remain at the forefront of their industry. Whether you are in automotive, aerospace, or consumer goods, the impact of rapid prototyping on your production line and overall business strategy cannot be underestimated. Embrace this powerful tool, and watch your business grow and succeed.

For more information on how DeepMould.net can assist you with your rapid prototyping service needs, visit our website or get in touch with our experts today!